In an era where the future of electric vehicles (EVs) is rapidly unfolding, LG Energy Solution (LGES) and Qualcomm Technologies have joined forces to unveil a groundbreaking solution aimed at significantly enhancing the longevity and performance of electric vehicle batteries.

This innovative system leverages a state-of-the-art system-on-chip (SoC)-based Battery Management System (BMS) diagnostic framework designed to offer EVs smarter, faster, and more accurate insights into their battery health.

By merging the power of Snapdragon Digital Chassis with advanced BMS diagnostics, this technology marks a pivotal advancement over traditional methods, offering a leap in capabilities that were once unattainable with conventional battery management systems. Gone are the days of rudimentary hardware; this collaborative solution provides the first-ever BMS implementation that integrates high-performance SoC computing, making battery diagnostics smarter, faster, and more efficient than ever before.

A New Era in Battery Management: Beyond Conventional Technology

Unlike traditional BMS systems, which have relied on low-spec hardware, the new LG-Qualcomm system brings an entirely new level of sophistication. The Snapdragon Digital Chassis gives this solution a computing power that is 80 times more efficient than its predecessors, enabling EV batteries to be managed and diagnosed with previously unattainable levels of detail. According to an official statement from LG, “This is the industry’s first BMS solution leveraging high-performance SoC computing power”, emphasizing the monumental shift this technology represents.

This breakthrough builds on the previous collaborative efforts between LGES and Qualcomm, focused on pioneering next-generation BMS diagnostic solutions. The integration of Snapdragon Digital Chassis provides an unprecedented opportunity to evolve battery diagnostics into a more accurate, timely, and comprehensive field, paving the way for better-performing and longer-lasting EV batteries.

Unprecedented Computational Power for Advanced Diagnostics

The true power of this system lies in its refined ability to conduct complex BMS diagnostics. By leveraging the immense computational potential of Snapdragon’s Digital Chassis, this system can handle and process an enormous amount of data—something that traditional systems simply could not manage. The result is a more robust battery management solution capable of providing in-depth insights into battery health, degradation, and safety diagnostics.

The Snapdragon Digital Chassis allows for enhanced safety diagnostics, detecting potential thermal incidents and battery failures in real-time. Unlike traditional systems that may only flag issues after the fact, this advanced system can detect anomalies as they occur, enabling immediate corrective action to be taken. This includes the early detection of thermal issues, which can prevent catastrophic failures in battery systems.

Key Features of the Advanced BMS Diagnostic System:

| Feature | Previous Systems | New BMS with SoC |

|---|---|---|

| Compute Power | Low Spec Hardware | 80x Increase in Compute Power |

| Thermal Incident Detection | Limited Detection | Real-Time, Precise Detection |

| Degradation Diagnostics | Basic, Simple Calculations | Detailed, Complex Algorithms |

| Data Collection | Limited Data Acquisition | Large-Scale Data Collection |

| Real-Time Diagnosis | External Server Required | In-Vehicle Diagnostics |

A System That Learns and Adapts: Enhanced Degradation Diagnostics

One of the most remarkable advancements offered by this new diagnostic solution is its ability to conduct detailed degradation diagnostics. Traditional BMS solutions often provided only basic diagnostics based on simplistic calculations. However, the Snapdragon-powered system utilizes complex algorithms to deliver a far more detailed analysis of battery performance.

The enhanced computing power, now 80 times more efficient, allows the system to perform predictive analyses with unprecedented accuracy. This refined degradation diagnostic capability can forecast battery lifespan, estimate remaining capacity, and pinpoint degradation in individual components like the anode and cathode. These improvements enable a much more granular understanding of how a battery will perform over time, providing both drivers and manufacturers with essential data for optimizing battery health and longevity.

“The degradation diagnostics will also be more refined, with compute power increasing over 80 times,” asserted the companies, adding that these advanced algorithms were previously unfeasible in conventional BMS systems. By moving beyond simple measurements, this system empowers users to monitor specific degradation performance indicators and make proactive decisions to extend the battery’s lifespan.

Real-Time Diagnostics and In-Vehicle Data Analysis

Another critical innovation introduced by this collaboration is the real-time diagnostic capability of the new BMS software. Unlike traditional BMS solutions, which often required a connection to a server for data analysis, this new system can process and analyze vehicle data directly within the vehicle itself. This means that battery performance and health can be assessed instantly, without needing to rely on external systems or waiting for scheduled diagnostics.

By integrating real-time analytics into the vehicle, drivers can immediately access information on their EV’s battery health, helping them make better-informed decisions on charging and maintenance. This approach also enables rapid detection of any potential issues before they escalate, offering an extra layer of safety and reliability for electric vehicle owners.

A Partnership That Promises Safer and More Efficient EVs

At the heart of this breakthrough is the collaboration between LGES and Qualcomm, both of which bring decades of expertise to the table. With over 20 years of experience in BMS design and data analysis, LGES has built a reputation as a global leader in battery management systems, with an impressive portfolio of over 8,000 patents in the field. Their commitment to safety diagnostics is evident, with a detection rate exceeding 90%, and their degradation diagnostics have a remarkably low error rate of just 1%.

On the other hand, Qualcomm is a powerhouse in the world of wireless technology, and its dedication to driving digital transformation in the automotive industry is evident through its cutting-edge Snapdragon Digital Chassis. This platform serves as the backbone for the development of intelligent, connected vehicles, integrating advanced technologies into the vehicle ecosystem to create smarter, safer, and more efficient transportation solutions.

The Critical Role of Battery Management Systems in EV Safety

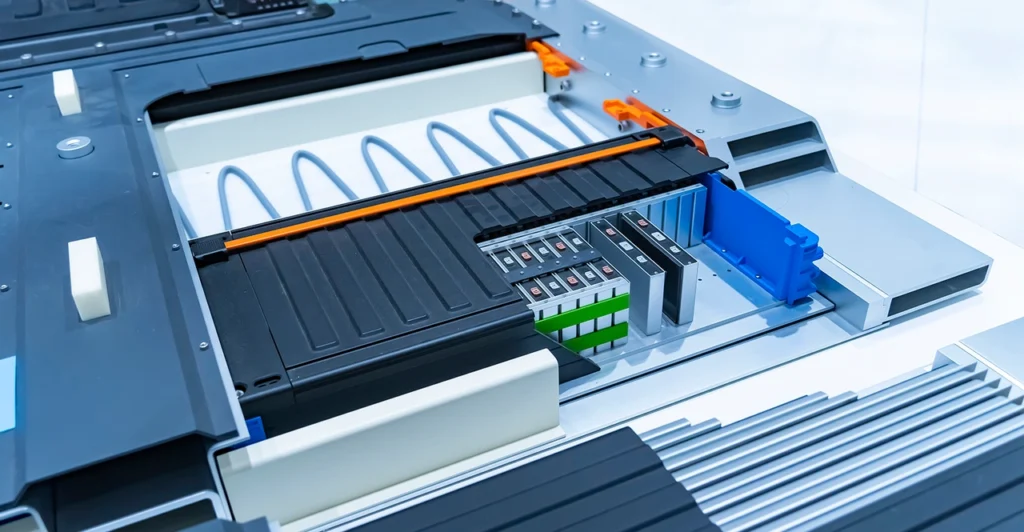

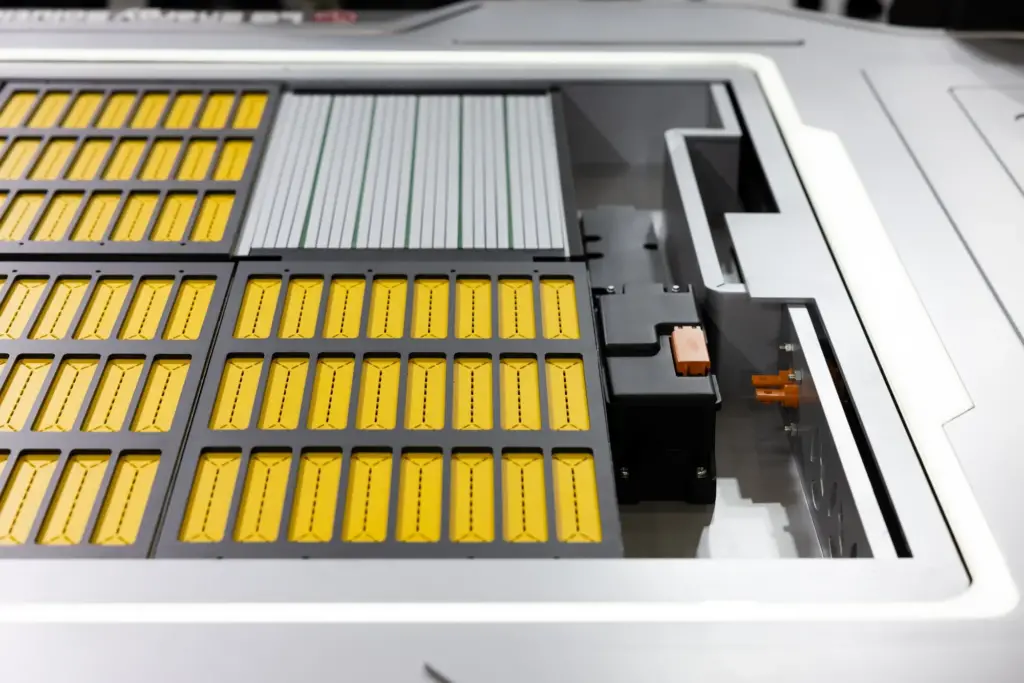

The importance of an advanced Battery Management System (BMS) in electric vehicles cannot be overstated. BMS systems serve as the guardian of the EV’s battery, protecting it from overcharging, over-discharging, and overheating—all of which can lead to catastrophic failures. They also monitor the battery’s state of charge (SOC) and state of health (SOH), ensuring that the vehicle operates at peak efficiency while maximizing battery lifespan.

Beyond performance optimization, a well-functioning BMS also plays a crucial role in safety. The ability to detect and respond to faults in real-time can prevent dangerous situations, such as thermal runaway or battery fires. Moreover, the system’s ability to balance the load across individual battery cells ensures that the vehicle’s energy source is fully utilized, maximizing the range and effectiveness of the EV.

The Future of EV Battery Management: Looking Ahead

With the integration of Snapdragon-powered SoC technology into BMS solutions, LGES and Qualcomm are positioning themselves at the forefront of the electric vehicle revolution. As the demand for EVs continues to grow, these innovative advancements will play a critical role in ensuring that electric vehicles are not only more efficient but also safer and longer-lasting. This collaboration marks the beginning of a new era for battery management systems, one where advanced computing power and real-time diagnostics are the keys to unlocking the future of electric transportation.

The potential for this technology to revolutionize the automotive industry is immense. By ensuring that batteries are healthier, longer-lasting, and more reliable, this joint solution offers a promising glimpse into the future of sustainable, efficient, and safe electric mobility.

As David Kim, CEO of LG Energy Solution, put it: “It is very meaningful that we have opened the market for the industry’s first SoC-based BMS, which will be key to the electric vehicle era, together with a global automotive technology leader like Qualcomm Technologies.”

Indeed, the next-generation EV battery management systems are here—and they promise to reshape the landscape of electric vehicle performance, safety, and sustainability for years to come.